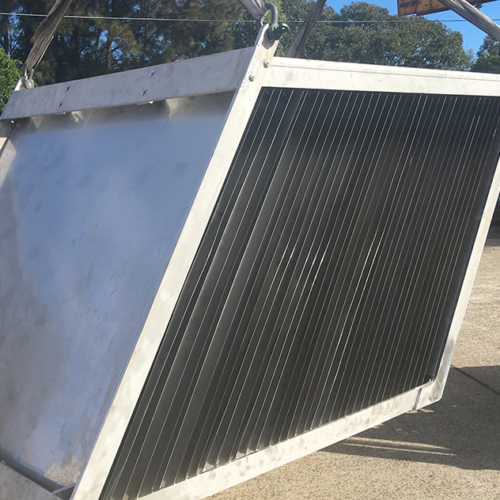

Lamellas

Hydroflux Industrial’s HySEP™ Solids Separators are designed, specifically for industrial, mining and high salinity applications. including Anodisers, tunnel construction, groundwater treatment, galvanising plants, manufacturing, and mining.

With over 60 years of design and commissioning expertise, you can be assured that your Hydroflux HySEP™ Solids Separator will perform consistently with a long service life.

All Hydroflux HySEP™ Solids Separators are fabricated from 100% stainless steel. This includes the body, weirs, plates, plate frames and hopper.

Find out more

HySEP™ Lamella separator features

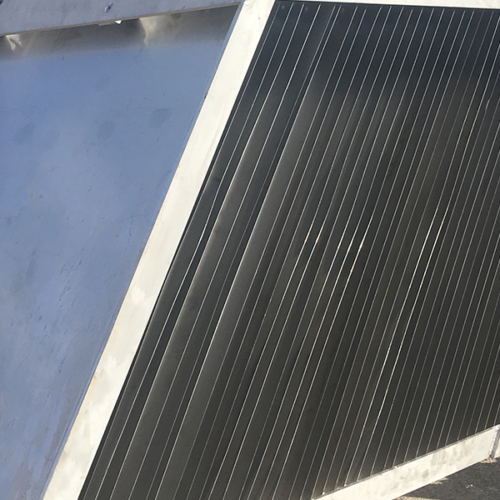

- Highly effective plate pack surface area with a non clogging crossflow lamella plate configuration

- All stainless steel lamella pack construction for chemical resistance (all grades of stainless steel available)

- Design to promote laminar flow conditions to optimise performance

- Free standing design in steel construction or concrete for larger applications

- Standard 60-degree plate angle with standard 20 mm spacing. 10 mm and 40 mm options

- 60-degree sludge hopper able to prevent rat-holing and improve solids removal

The following video shows how the Hydroflux HySEP™ lamella separator operates.

Stainless steel lamella plates can be spaced at 10 – 40 mm

The HySEP™ Solids Separator range is available in the following standard sizes:

| Model | Plate Area* | Flow Rate** |

| CS5 | 6.1m2 | 5.0kL/hr |

| CS10 | 11.5m2 | 10.0kL/hr |

| CS20 | 20.9m2 | 20.0kL/hr |

| CS30 | 31.3m2 | 30.0kL/hr |

| CS40 | 41.7m2 | 40.0kL/hr |

| CS60 | 62.6m2 | 60.0kL/hr |

| CS80 | 84.6m2 | 80.0kL/hr |

* Plate Area Projected @ 60°

** Flowrate Subject to Application

“What is the difference between a lamella separator, inclined plate separator and clarifier”

“What is the difference between a lamella separator, inclined plate separator and clarifier”

There is no difference between and inclined plate separator and lamella plate separator, it is just the terminology. The plate separator as the name suggests contains inclined plates that increase the effective surface area of the unit allowing treatment in a smaller footprint than a conventional clarifier.

Does it need chemical addition to work effectively?

This depends on the type of solids that are being removed and the quality of treated water required. A dose of coagulant and flocculant will certainly improve the solids separation however this is not always necessary.

Does a HySEP™ lamella block easily?

The Hydroflux CS Lamella range is designed for industrial applications where high solids loads are usually experienced. The spacing between the plates is selected based on the type of solids and the solids load in the raw water to prevent blockages from occurring. That said, “sticky” types of solids can adhere to plates resulting in potential blockages in which case the conventional type of Hydroflux clarifier may be a preferable selection.

What do I do with the sludge removed from the water phase?

The sludge that is collected in the base of the CS Lamella is usually transferred to a dewatering process such as a filter press or screw press.

What is the settling rate used on the design?

The standard settling rate use in the sizing tables to calculate the nominal flow for each model is 1 m/hr. Sizing of the units is different for every application as the required settling rate varies depending on the solids that are being removed and the pate spacing.

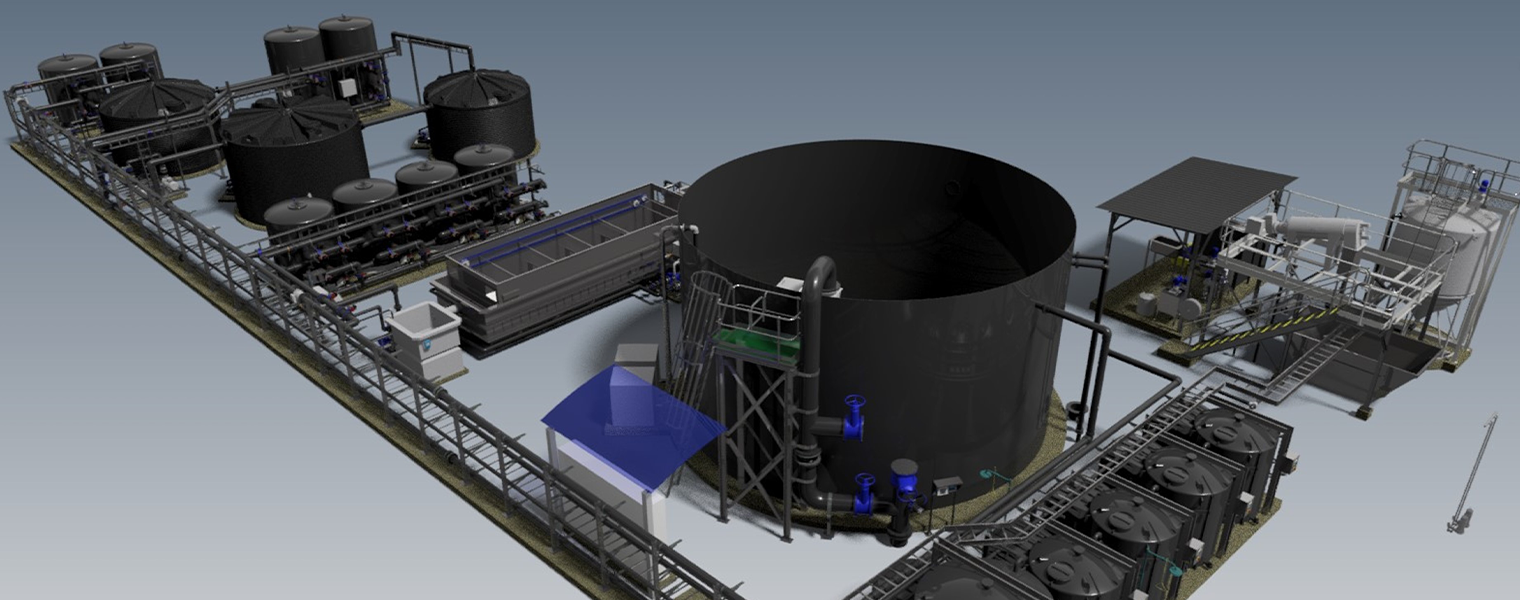

The HySEP™ Solids Separator is just one process component in complete water or wastewater treatment plant and is usually supported by a range of ancillary process operations to condition the influent, handle the sludge generated, or provide further treatment or recycling. Hydroflux has the skills and expertise to conduct any design and construct project incorporating a Lamella Separator.

Hydroflux employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices throughout Australia providing a local presence throughout the duration of the project.

All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Hydroflux design and construct complete wastewater treatment systems involving lamella separation technology.

Hydroflux is Australia’s first Water-tech company to achieve Climate Active certifications which means by engaging with Hydroflux you are supporting positive and verified action on climate change.

Construction of a turnkey wastewater treatment plant at a new food production facility in SA

The Utilities division provides the link to integrating the Hydroflux® businesses by providing a comprehensive support network for customers throughout New Zealand.

Hydroflux Utilities provides virtually any form of wastewater management programs including:

Chemical optimisation

Hydroflux has a comprehensive range of coagulants and flocculants suitable for conditioning wastewater or sludge. The most appropriate chemical program will be determined before commissioning based on experience, or test work if possible, and long-term cost-effective chemical supply contracts can be arranged.

Preventative maintenance and service

Our engineers and technicians will discuss service and maintenance programs with you during construction of the wastewater treatment plant so that you can be assured that the system will perform consistently from day 1. There are many types of programs available from routine preventative maintenance, periodic service and overhauls, to complete plant operation. Our technicians are available 24/7 to attend to unforeseen breakdowns.