Manufacturing

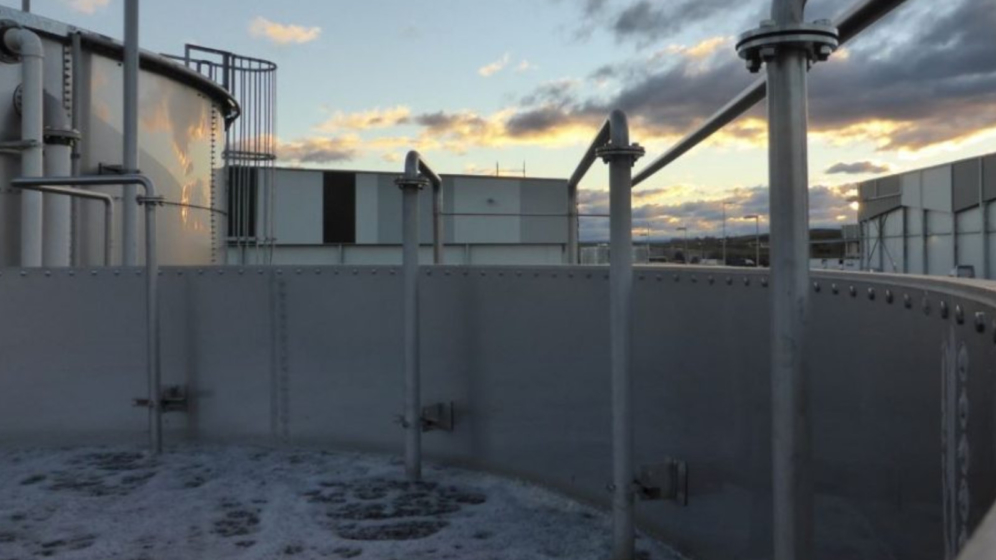

Globally today there are thousands of different types of manufacturing processes that generate wastewater. The manufacture of so many different products creates a truly unique water challenge, where no two manufacturing plants are the same.

Even is cases where sites may manufacture the same product mix, their locations, climate, water availability and discharge locations all mean the water and wastewater solutions for that site need to be tailored specifically.

The Hydroflux team has a unique understanding of the requirements to treat wastewater from all types of manufacturing processes with knowledge and experience in the production cycles, the typical profiles of the wastewater and how that impacts on the design of the wastewater treatment plant to meet various discharge requirements including reuse.

We also have extensive experience in the design and construction of hygienic process water systems necessary to ensure product quality where necessary.

Some of the industries we support include:

- Petrochemical

- Pulp and Paper

- Oil refineries

- Metal processing

- Tanneries

- Personal care

- Pharmaceutical

- Printing

HyPURE® RO Systems

The Hydroflux HyPURE® range of brackish water reverse osmosis systems’ offer high efficiency, a low energy design and exceptional performance…

Biological Treatment

Biological treatment can treat wastewater to achieve very low levels of organics and nutrients. When aerobic treatment processes are incorporated…

Multimedia Filtration

The HyPURE Multimedia filtration system is a compact, robust and economical solution designed and manufactured by Hydroflux. With nearly 50…

CoverSweep®

The CoverSweep® launder covers eliminate problems associated with excess algal growth in clarifier launders. The CoverSweep® system is a series of interlocking fibreglass or…

Concrete Tank Design

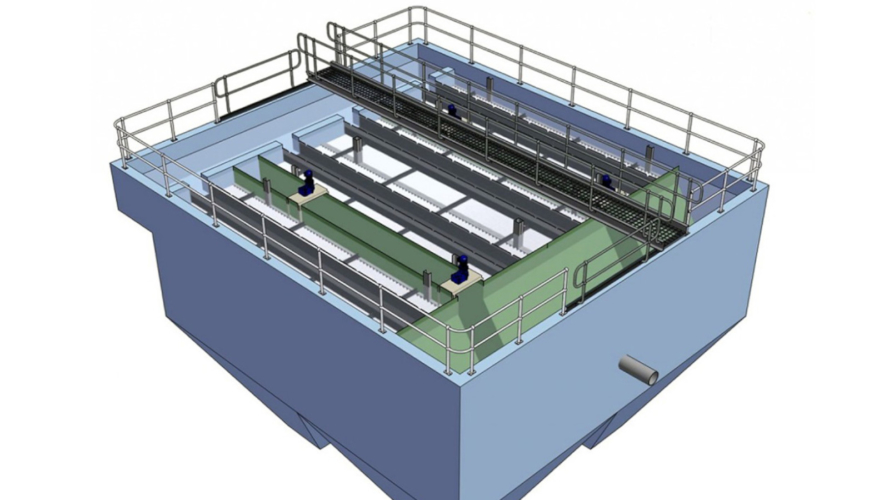

HiFlowTM can be provided in concrete tanks for larger applications. The HiFlowTM plate packs are installed within the concrete tank…

Free Standing Design

HiFlowTM can be provided as a free standing tank, that is fully assembled prior to delivery. This reduces site installation…

CrossFlow™

Hydroflux Industrial’s CrossFLOW™ Solids Separators are designed, specifically for industrial mining and high salinity applications. Including Anodisers, glass factories, tunnel…

Primary

Clarification processes are commonly used in as the first stage of solids separation in water, sewage and industrial treatment systems….

Secondary

Continuous biological wastewater processes typically use secondary clarifiers as the phase separation step to separate biomass from the water phase….

Tertiary

Tightening discharge limits requires the use of tertiary filtration for the removal of fine suspended solids, nutrients, bacteria and pathogens….

Sea Water

Tightening discharge limits requires the use of tertiary filtration for the removal of fine suspended solids, nutrients, bacteria and pathogens….

Stamford Baffles

Hydroflux® can provide Stamford baffles below the launder system. These baffles eliminate density current flows that can disturb sedimentation of…

Scum Removal

Scum collection and removal from clarifiers water surface can be effectively facilitated via a radial surface scum scraper with a…

Solids Contact Clarifiers

Hydroflux offers Solids Contact Clarifiers for applications where the incoming solids load is low, or the chemical flocc is fragile,…

LaunderShield®

The LaunderShield® launder covers eliminate problems associated with excess algal growth in clarifier launders. The LaunderShield® system is a series…

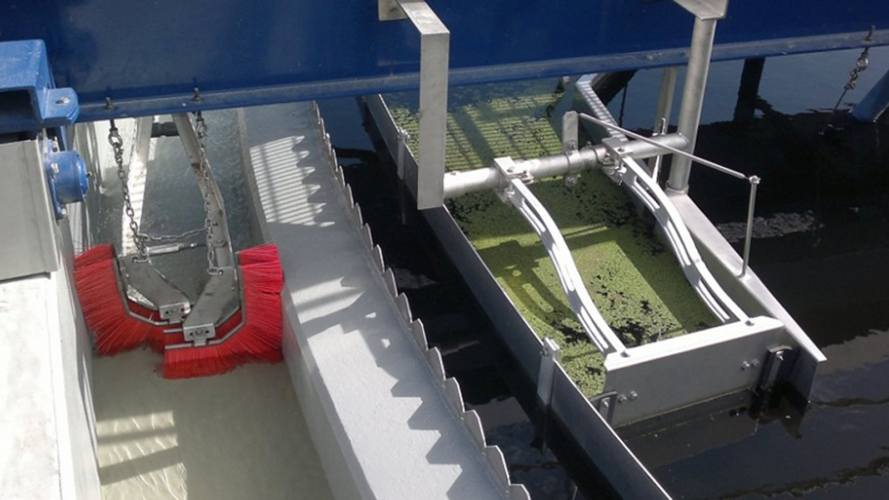

CleanSweep®

The CleanSweep® roller brush combats the Algae problem in clarifier launders head on The CleanSweep® approach divides the launder trough in to…

EdiGate®

EdiGate® is specifically designed to eliminate the need for mechanical mixing in the flocculation zone of clarifier feed wells. Available…

HeadMax®

The HeadMax® hydraulic suction system is designed for sludge removal in activated sludge treatment with partial or complete nitrification processes….

LogMax®

The LogMax® logarithmic sludge plow is designed for collection of lighter suspended sludges. While optimum angle is approximately 30° at…

VeeMax®

The VeeMax® Chevron pattern sludge plow is designed for heavy, relatively viscous, sludges such as those in water treatment where…

Sludge Thickeners

Thickening of sludge using sedimentation is a common method of increasing the solids concentration due its simplicity of operation, low…

Lime Saturators

The lime saturator is a process unit, designed to make saturated lime water for control of the pH and alkalinity…

Solids Contact Clarifiers

Hydroflux offers Solids Contact Clarifiers for applications where the incoming solids load is low, or the chemical flocc is fragile,…

Tertiary Clarification

Tightening discharge limits requires the use of tertiary filtration for the removal of fine suspended solids, nutrients, bacteria and pathogens….

Secondary Clarification

Continuous biological wastewater processes typically use secondary clarifiers as the phase separation step to separate biomass from the water phase….

Primary Clarification

Clarification processes are commonly used in as the first stage of solids separation in industrial wastewater treatment systems and various…