Efficient Sewage Solutions for Mining Camps

January 16, 2024

In the remote locations where mining sites house their workers in residential-style camps, the need for safe and efficient sewage treatment is paramount. However, these camps often face extreme environmental challenges due to their isolated settings.

Australia’s mining industry is predominantly situated in sensitive environments with shared water resources, influenced by cultural and economic factors. Notably, various stakeholders, including traditional landowners, access valuable water assets like the Great Artesian Basin and the Murray Darling Basin.

Mining operations must integrate efficient water treatment solutions, contribute to urban and pastoral water supplies, support ecological restoration efforts, and implement robust monitoring systems. They must also be adaptable to cope with fluctuating water supplies and varying types of contaminants.

Historically, sewage treatment discharge was primarily cleaned for release into local creeks, achieving treatment quality so high that 100% of the effluent could be repurposed for flushing toilets, watering gardens, and doing laundry.

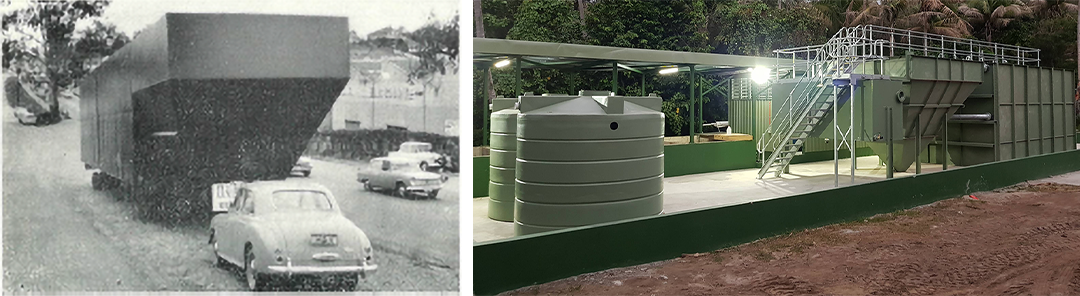

Hydroflux has been installing and upgrading RoadTrain® sewage treatment systems in the mining industry since the 1960s. These systems are tailored to accommodate varying camp sizes, environmental conditions, local water sources, and potential contaminants.

One early example is the Blackwater lease for BHP Mitsubishi Alliance in 1978, where six welded RoadTrains spanned 40 km of land. Over the years, Hydroflux has continually enhanced these systems with additional equipment and technologies to ensure they meet modern compliance standards. Compliance requirements have evolved significantly since those early days. Moreover, these systems are designed to be relocatable as mining operations shift along the coal seam, offering considerable economic advantages through asset reuse.

Scalability is another economic benefit. For instance, a RoadTrain package initially set up in the Bowen Basin coal mine in central Queensland in the 1970s had a capacity for 400 people. Through a series of relocations and upgrades, it was capable of accommodating up to 800 people by 2012.

Today, pre-fabricated sewage treatment systems are available and can be easily installed on concrete slabs. These systems are delivered to the site in a flat-pack format, alleviating logistical challenges for sites with limited road access or the absence of cranes. This approach was successfully employed for a bolted RoadTrain® installation at Moro village within the Oilsearch mining lease in Papua New Guinea’s southern highlands in 2015.

Explore the images of RoadTrain® installations, spanning from the 1960s to recent developments.

Hydroflux specialises in designing, building, installing, and refurbishing sewage treatment plants for mining site accommodation camps. Additionally, they offer comprehensive support and maintenance services for your installation.

For more information on Hydroflux Epco’s RoadTrain® please click here. For more insights into Hydroflux’s capabilities in the mining industry, please click here.

RoadTrain® is a registered trademark of Hydroflux Epco Pty Ltd.

About the Hydroflux Group

The Hydroflux Group aims to deliver the highest level of engineering and scientific know-how to the emerging issues of sustainability, climate adaptation and environmental protection with a specific focus on water and wastewater.

As part of its vision and mission, Hydroflux has always taken its climate responsibility seriously. In 2022, Hydroflux became Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for its organisation and products. It knows that partnering with customers and clients is the most significant impact it can have in its journey. The Group employs over 100 staff and operates throughout Australia, New Zealand and the Pacific Islands, with office locations in Sydney, Melbourne, Brisbane, Perth, Auckland, Suva and Portsmouth.

Up Next

AirPrex® – Addressing the Issue of Struvite Formation in BNR Plants

Hydroflux Group Newsletter – December 2023

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement