Resolution for Algal Growth in Waste & Wastewater Treatment Systems

May 19, 2022

In Australia, ponds, lagoons, rivers and lakes form a significant part of the industrial and municipal water cycle. These “surface water” systems make up essential parts of both the water supply and wastewater treatment stages of the cycle. In recycled and advanced water processes the surface water systems form part of both the water and wastewater treatment. The relatively low cost to use surface water supplies, as well as the robust nature of pond/lagoon systems in wastewater treatment, make surface water systems extremely popular.

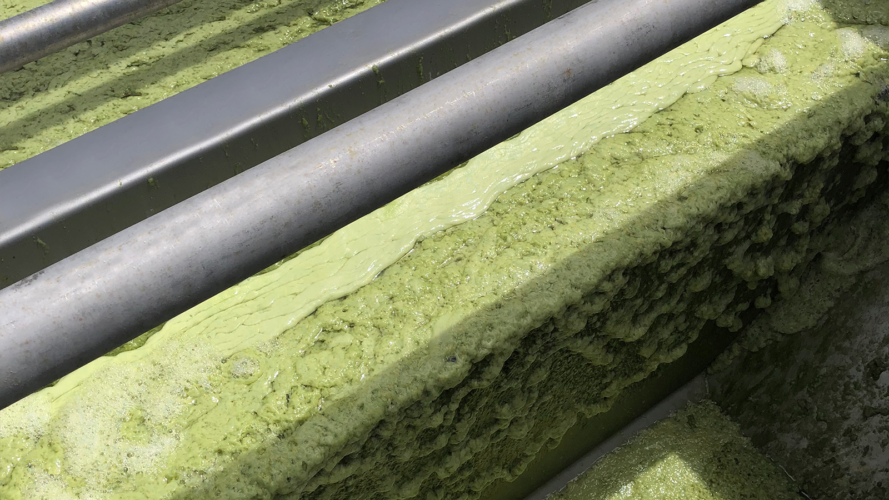

A major drawback for existing plants is algal blooms. Wastewater ponds & lagoons for anoxic treatment and final waste stabilization are also regularly consumed by algal blooms. Ineffective denitrification or chemical/biological phosphorus reduction within the pond leads to extensive algal blooms. Algal blooms create significant operation and maintenance issues for filtration systems within potable water and wastewater recycling systems. Although algae are treated as simple plants, they pose a threat to all potable water and tertiary treatment systems because of “fouling” issues. Fouling is caused by algae’s small spores which become lodged within the roughened surfaces found within packed media and membrane filtration systems. Over time, the filtration systems block from the buildup of cellular material on the filter media. This fouling has a severe impact and rapidly reduces treatment plant performance. To exacerbate the issue, dead and decomposing algal cells provide the necessary nutrients for other forms of anoxic and anaerobic bacteria to thrive, leading to biofilm formation on filtration media and throughout the treatment plant. Replacement costs for membranes in potable and process water plants can be significantly reduced by the effective removal of algae in the feed water supply.

Some algal strains are more problematic than others. One particularly problematic type found regularly throughout Australia is blue-green algae. Blue-Green Algae, (a type of cyanobacteria) blooms are harmful to human health, animals, and the environment. Disinfection of water through chlorination is regularly used to control the growth of microbiological organisms. Blooms of cyanobacteria generate toxic secondary metabolites called cyanotoxins during routine chlorination of treated water. Health impacts of exposure to cyanotoxins in drinking water include, but are not limited to; damage to the kidneys, liver and gastroenteritis.

Aside from cyanotoxins, by-products of chlorination include the production of trihalomethanes. Primarily, trihalomethanes (THMs) are compounds produced in the reaction between the chlorine used for disinfection and organic matter present in the water. If present in high concentration, THMs can impose negative health effects like cancer. THMs are tightly regulated in many food industries, which often need high-grade process & potable water for production. The presence of algae in surface water supplies and subsequent THM increase can lead to product quality issues within the production facility.

Controlling algal blooms can be difficult, in many instances nutrient reduction within the surface water system may not be possible. Many surface water supplies are dogged by season blooms associated with nutrient run-off from agriculture, which cannot be controlled. Similarly, the costs to upgrade ponds/lagoons to enhance their nitrogen or phosphorus removal rates may be prohibitive. In instances such as these, alternative treatment to remove algae from the water is required.

Dissolved Air Flotation (DAF) applied correctly, is a highly effective process in resolving the problem of algae accumulation. DAF is a treatment process that clarifies wastewater through the removal of suspended solids by modifying pollutant particle density through air bubble attachment. The removal is through a process of dissolving air in the water under pressure in a flotation tank. More details on the dissolved air process can be found here. The advantage of DAF over other clarification technologies for algae removal is the typical bubble size of 10 – 40μm is perfect for attachment to the fine algae flocs. The algae cells do not have a sufficiently high density to naturally settle at a rate useful for clarification. To enable settling, the algae floc size must be several orders of magnitude larger in clarifiers than for DAF technology resulting in higher chemical costs. Due to this relatively low particle density, only a small application of air is required to separate the algae from the wastewater. This means that footprint and capital costs for the DAF system are also relatively low. For water treatment projects driven by financial returns, a typical DAF system can offer ROI’s of less than 10 to 12 months due to significant savings in downstream treatment process operation and maintenance costs and higher overall treatment capacity.

The real challenge for wastewater treatment engineers is the management of the chemical addition process. Coagulants and in some cases, flocculants are mixed with the water to enhance the removal rate of algae. The algae cells can be highly shear sensitive if not treated carefully during the coagulation process, preventing any subsequent separation. Furthermore, excessive coagulant and flocculant chemical dosages used to compensate for the effect of shearing can have a detrimental effect on downstream membrane processes as well as unnecessarily increase operating costs. Specialist DAF systems for algae removal, such as the HyDAF process have modified chemical injection techniques for optimizing algae floc structure whilst minimizing chemical dose rates.

DAF also generates a more concentrated waste sludge stream. This sludge can then be dewatered further using either HUBER Inclined Sludge Press. These solids are loaded with the nutrients taken up by the algal cells and are ideal for composting or use as a fertiliser.

As our finite water resources become more and more stretched, the need for alternative sources of supply will grow. Industry and the public will look further into the treatment of nutrient-loaded surface water or wastewater to provide a reliable source for potable and process water. The need to ensure these sources can be safely and reliably treated will need to consider the impact of algal blooms on their processes.

For more information on the Hydroflux DAF system, please Click Here.

About Hydroflux

The Hydroflux Group consist of eleven specialist companies which aim to deliver the highest level of engineering and scientific know-how to the emerging issues of sustainability, climate adaption and environmental protection with a specific focus on water and wastewater.

The Group employees over 100 staff and operates throughout Australia, New Zealand and the Pacific Islands with office locations in Sydney, Melbourne, Brisbane, Perth, Auckland, Suva and Portsmouth.

Contact

Hydroflux Pty Ltd

Level 26, 44 Market St. Sydney NSW 2000 Australia

P +61 2 9089 8833 F +61 2 9089 8830

[email protected]

Want to stay up-to-date with what is going on? Click Here to follow us on LinkedIn

Up Next

Hydroflux Expands Its Western Australian Presence

Leachate – What is it and Why is it a Problem?

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement